Colmar Report Work package 2 - Activity 2

Date:

Monday, 15.01.2024 - Friday, 19.01.2024

Time:

9:00 a.m. – 4:00 p.m.

Place:

Lycee Blaise Pascal Wood department, Rue du Logelbach 74, 6800 Colmar France

Members:

Students: Claas Petersen, Johannes Oldörp, Mikko Tuomisto, Tobias Mikkola, William Barker, Lorenzo Fadigas, Paul Meyer, Adam Schubnel, Ditte Handreck, Signe Sofie Bröndsholm Hansen, Jiri Novy, Marek Rubes, Paula Beckmann, Paul Brandenburg

Teachers: Pascal Michel, Hans Janßen, Ulli Fregin, Judith Köpke, David Schütz, Matti Jokinen, Jukka Jussila, Cedric Girroy, Alexandre Neff, Arkadiusz Kulon, Jan Holmberg, Zuzanna Porizova, Vaclav Kulhanek

Monday, 15.01.2024

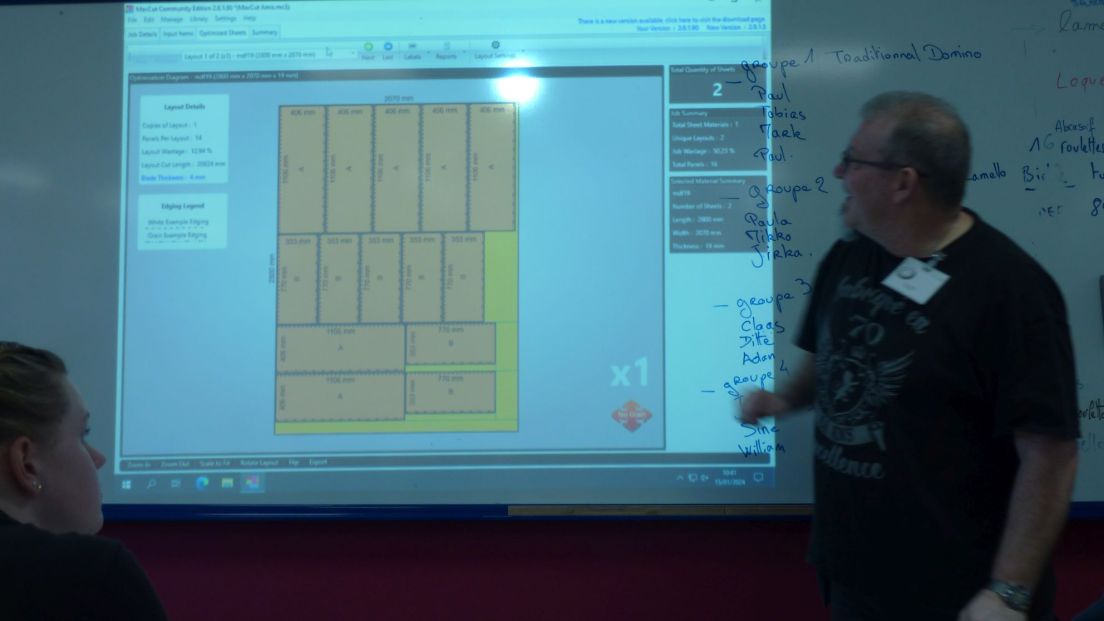

On Monday morning, the participants met in the workshop of the vocational school and first took a tour of the school workshop. The teacher in charge, Pascal Michel, explained the use of the most important standard machines and explained the safety regulations for working on machines. The functionality of the vertical panel sizing saw was explained and then the participants were given the task for this working week. A total of 4 cabinets for a kindergarten are to be produced in 4 teams. The board material should be made of MDF and the cabinets should not be painted by the participants. The children in the kindergarten take on this activity. The next step was the presentation of the Maxcut software in the workshop classroom. A cutting plan with dimensions was printed out for the entire number of MDF panels. Now the panel cutting could begin and the mixed teams were put together. The following plan was decided: 2 cabinets should be manufactured using the CNC machine, one cabinet should be produced by using lamello springs and one cabinet should be built with domino connectors.

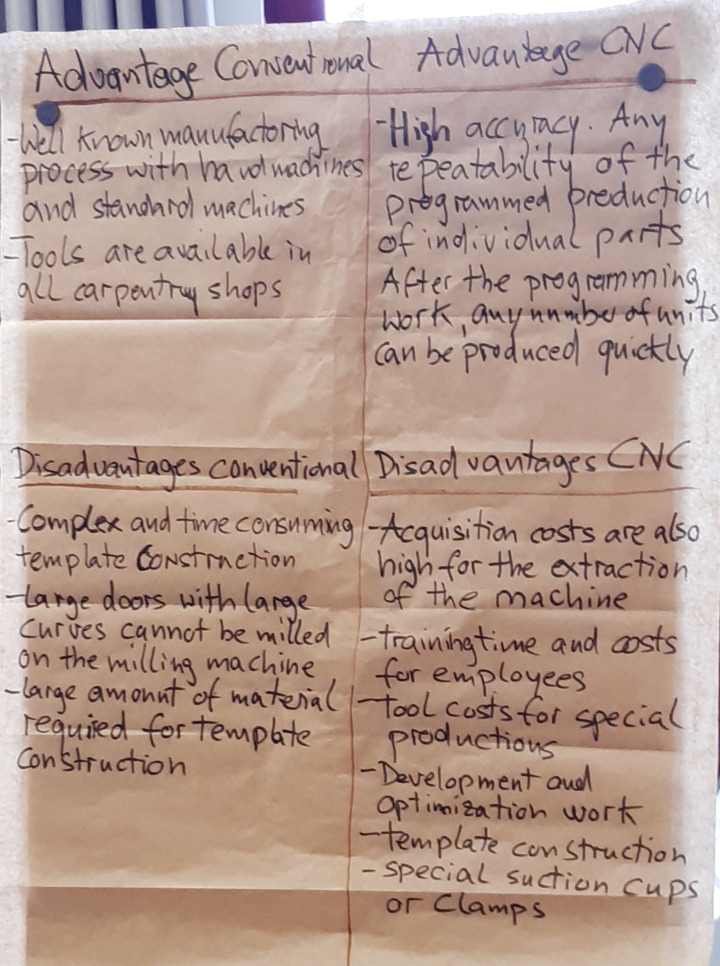

The aim of the project was to compare these production methods. The trainees discussed the work steps in their teams and drew up a work flow plan. The individual parts of the cabinets were cut to size and the holes and millings were marked.

Tuesday, 16.01.2024

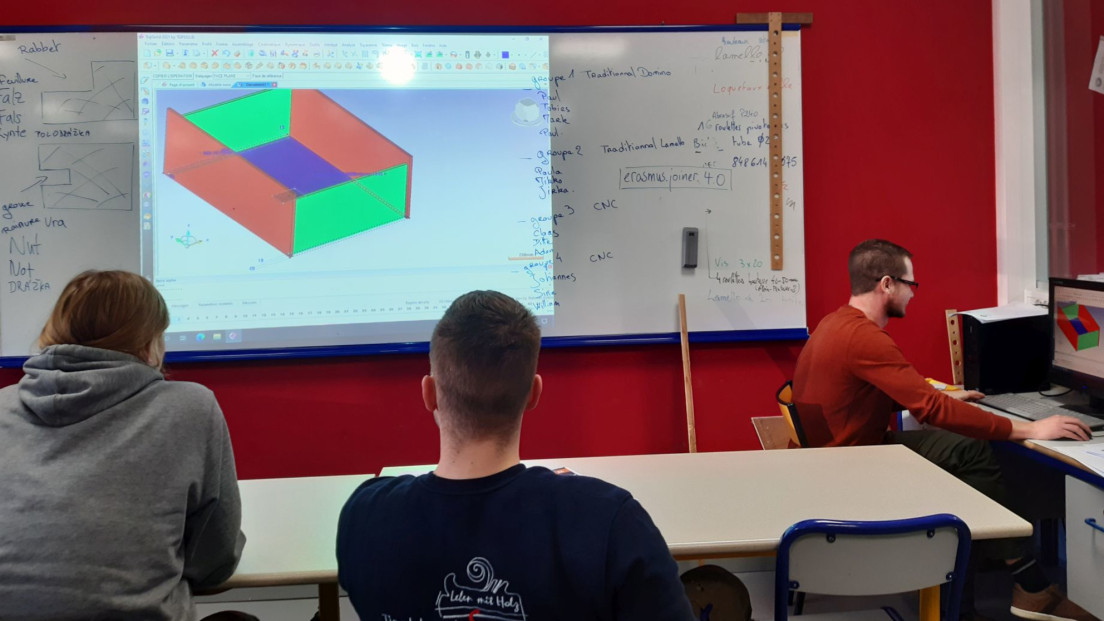

The next morning, a teacher gave a presentation of the 3D software Topsolid to the entire group, during which the students were able to see how the individual parts of a drawer were drawn and put together. The exact dimensions for the 4 cabinet packages were then determined and cut to size. The students made assembly marks on the individual parts so that the assignment of the individual parts to the cupboard was correct. In the early afternoon the first parts were milled and drilled on the CNC machine. The production teams using the conventional method (Lamello and Domino) carried out test milling and were able to mark the exact positions on the individual parts.

Wednesday, 17.01.2024

The Wednesday morning, we had to cancel the visit from the factory that is called Cuisine Schmidt because of slippery weather condition and all the transportation in Colmar were not allowed. All the groups were very busy on work and used the new time to follow the producing activities: Lamello cutting, Domino drilling, 32 system drilling, and realization from template to realize the rounded pieces. Afterwards they had to do the programming of the quarter circle and the plinth.

At the end of the afternoon we visited a museum that is called Musee Unterlinden. This museum have an archeological part from the Alsace history and also on the first level some old piece of furniture that are over 400 years old. And one famous church element that is called the Retable d’Issenheim it’s a painting with a main part and several shadows painted that will be open on a special time in the year.

Thursday, 18.01.2024

The different groups begun with the sending of different parts and also gluing the cabinet corpus together. In the same times the groups made the doors by CNC for some and traditional way for the others with the molding machine and a copy ring and finished with the hand router because one radius was to big for the molding machine.

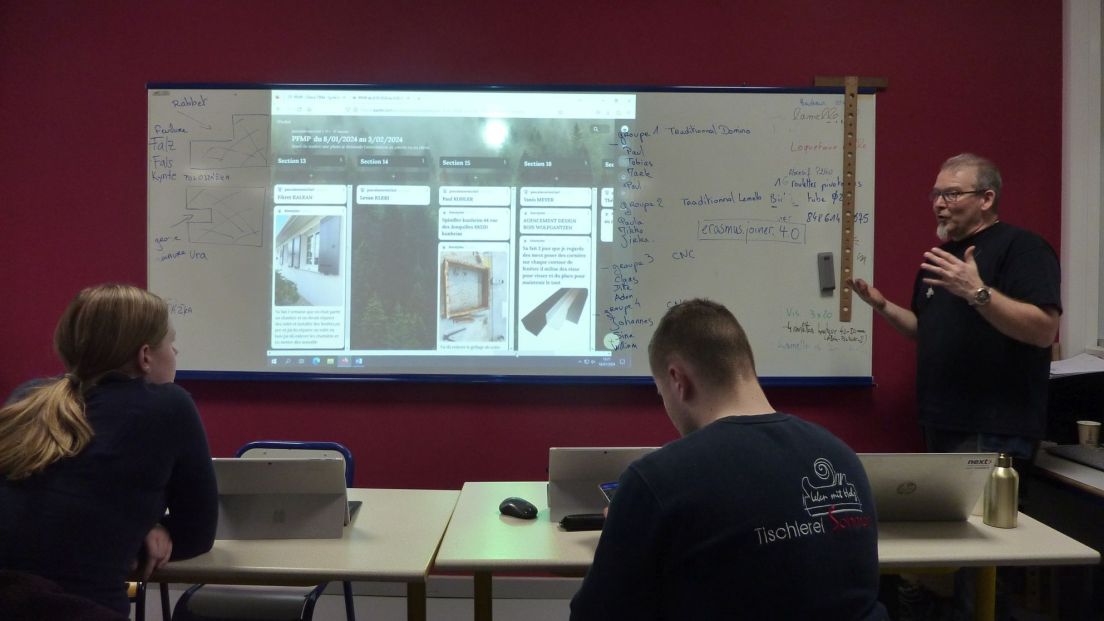

In the beginning of the afternoon Pascal shows us the digital diary that they use when the students are on work placement. This diary is called Padlet and it can be used from the mobile or a computer, you have a QR code to flash and you arrive on the class page to ad photos and texts to explain technical parts of the work done in the day. David also shows us some of the interactive video that they made in Stade in order to make our own for the project.

In the evening we met all at the Meistermann Restaurant to eat an specialty from Alsace called Baekaoffe.

Friday, 19.01.2024

All the groups put the doors on the place and control if the finishing was good. We took photos from the groups with each products and also a full group photo. Then we made the evaluation for the project week and talked about the problems and the differences between the two ways of producing. At 12 o’clock all the participants left the school to take the train back to their home cities in Finland, Denmark, Czech Republic and Germany.