Lübeck Report Work package 3 - Activity 3

Date:

Monday, 20.01.2025 - Friday, 24.01.2025

Time:

8:30 a.m. – 4:00 p.m.

Place:

Emil-Possehl-Schule Lübeck

Members:

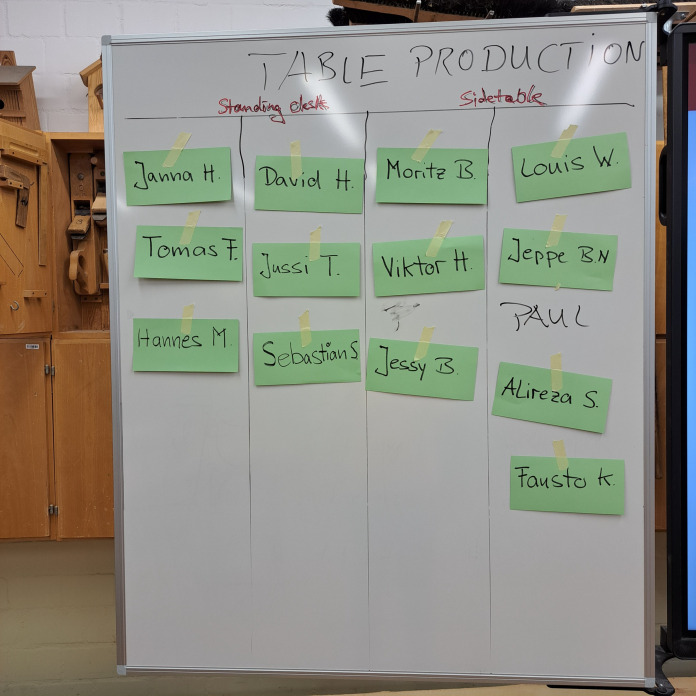

Students: Jussi Toivanen Gray, Alireza Shojai, Paul Kohler, Louis Weiss, Viktor Hoeyer, Jeppe Broberg Nielsen, David Horak, Tomas Folwarczny, Moritz Bach, Janna Hildebrand, Jessy Berg, Hannes Mielke, Sebastian Schmiedeke, Fausto Klenner.

Teachers: Isabelle Ladrat, Pascal Michel, Jukka Jussila, Ismo Pentinlehto, Ulli Fregin, Hans Janssen, Sidsel Inge Feldstedt, Serge Raymond Bossmann, Jakob Ulrich, Karla Vichova, Karel Cihak, Anja Waskow, Torsten Brunckhorst, Jan Gerke.

Monday, 20.01.2025

On Monday morning, we were warmly welcomed by the headmaster and the joiners team. We were given an introduction to the projects (two standing desks and two side tables are to be built in ash) and we had a tour of the workshop. There is even a great extra project for teachers: to produce a board game named ‘Church In The Town’ in a series of 30 pieces. Then, we started with the division of three groups because the whole day was dedicated to the introduction to the digital machinery systems: the trainees learnt the basics of the Pytha 3D CAD programme, CNC programming with Woodwop and they also got an introduction to the digital hand router Shaper from Festool.

Tuesday, 21.01.2025

This morning, we visited the company Treppenbau Voss. We were given an insight into the digital measurement system Flexijet. The manager showed us how to use the Laser measurement system from Flexijet. We then went through the various departments of staircase production. We started in the work preparation department, where the digital measurements are read into the CAD programme on the computer for further planning of the staircase. The production documents such as drawings, parts lists, etc are then printed in a folder for the workshop. We then visited the other departments like the cutting, the CNC production, the sanding station. The CNC production 4.0 was really impressive, with improved cutting planning and workflow planning. Many thanks to Reiner Vos from Treppenbau for this very interesting tour.

After going back to school, and after having a very delicious lunch composed of soups, students started their projects. Two groups of six students are working with standard machines while the other group is working with CNC. The trainees started to sort out and group their pieces of wood: pieces for the table legs, for the upper and lower frame, the top frame, and so on. They used the circular saw to cut each part and then the planer for the thickness and the width.

On Tuesday evening, we experienced a guided tour of old Lübeck, strolling in discovering narrow streets; we learnt a lot about the different architectural styles such as Gothic and Renaissance . Many thanks to Gerhard Ströh who was a very passionate guide.

Wednesday, 22.01.2025

The trainees resumed their work on their projects: some students cut the angles with the circular saw, and then they made templates either for drilling the frames of the side table, or dowelled holes for the legs of the standing desk. In order to get the tenons, the trainees used the circular saw and the bandsaw. So as to make the mortices on the table legs, they used the router. The day was a lot about making the mortises and the tenons, and a group of students spent a lot of time on the CNC programming so as to manufacture the tenons.

Thursday, 23.01.2025

This morning the group who worked on the side table with digital machines went to the CNC to manufacture the tenons while another group was sanding all the parts of the standing desk.

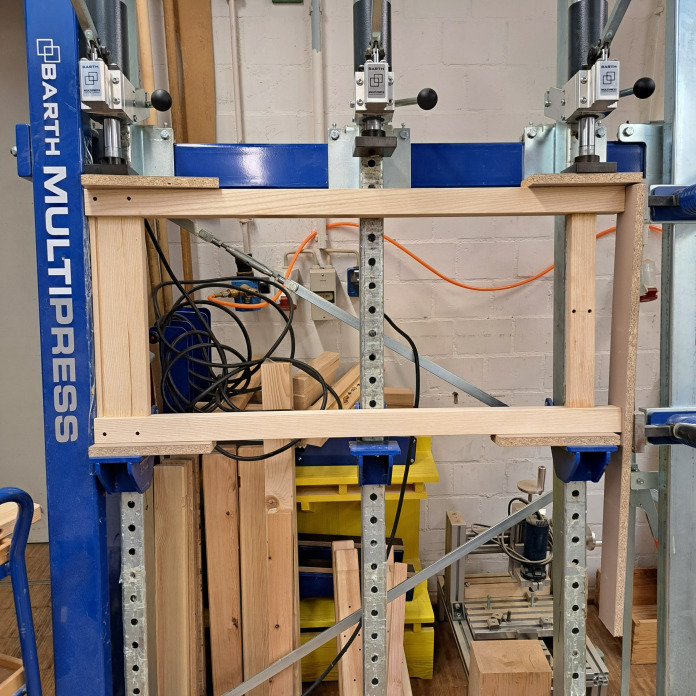

Most of the morning, the trainees cut off the legs of the table with the bandsaw. Then they used the moulding router to make the chamfers of the 3 crossbars. For the assembling, they have dowelled and glued the lower parts and the crosspieces are assembled by mortises and tenons.

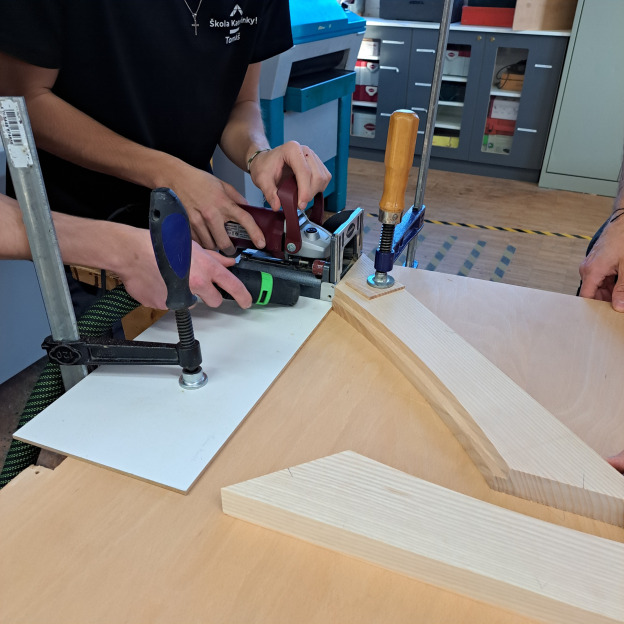

In the afternoon, some of the students worked on the CNC machine to manufacture the top frame of the standing desk, where some linoleum was glued. They also worked to manufacture the top frame of the triangular side table : the CNC cut 3 pieces which, once joined together, form a triangle in the center of the top frame. In order to join and fix them together, the trainees used a portative lamello machine in order to make grooves,so as to put the biscuits into the grooves. The top frame was simply placed and not fixed because the student wanted to bring it back home. In order to fix it, it would have been wise to fix it with dowels.

For the finishing they sanded the wooden surfaces to remove any rough edges and to be ensured to get a smooth finish. Then they applied varnish or oil to protect the wood and enhance its appearance.

To conclude, just a few words about the project that the teachers are doing: at the end of the afternoon, it was completely finished: the whole team worked quickly. All the game pieces have been cut off, and the clergyman paint lacquered in black ink. The gameboards were cut and after sanding all the parts, we packed each game part in each small bag in canvas. In order to personalise it, we have laser engraved the Erasmus Joiners 4.0 logo topped with the symbol of the city of Lübeck: The Holsten Gate.

Friday, 24.01.2025

As several of us had to leave at different times, we made the evaluation in the PC room, took the group photos, gave the Erasmus certificates and a board game to each of us. We also made a reviewing of these few days spent together.